- It does Speedboat in less than 6 minutes and is capable of doing high quality prints in 1/10th of the time a Ender 3 would need.

- By the time releasing, The 100 is at the 26th rank of the leaderboard of the fastest printers in the world and it's the fastest one that uses a 3d printed frame.

- And the best thing, this printer 100% open source. Which means if you like this printer and you like to build one by own, you find all resources needed to do this in this repository

- Bill of Material

- Join our Discord Server

- Support this Project on Patreon

- Grad the CAD files

- View the Assembly Guide

- Follow the Development

- Our Community on Facebook

- Printers build by the Community

To print the STL files, a 3D printer with a print bed of at least 230x230mm is required. I've printed all parts out of PLA. If you plan to print ABS/ASA on the printer i would suggest to print the print bed out of a more temprature resistant material.

For all STL Parts exept the print bed i've used the following settings:

- 0.25 Layer height

- 0.5 Line width

- 3 Top layers

- 3 Bottom layers

- 3 Walls

- 25% Infill

- Grid Infill Pattern

For the print bed:

- 30% Infill

The infill of the print bed needs to be slightly higher to move the center of gravity to where the lead screws are attached. This is needed to stop binding on the Z-Axis.

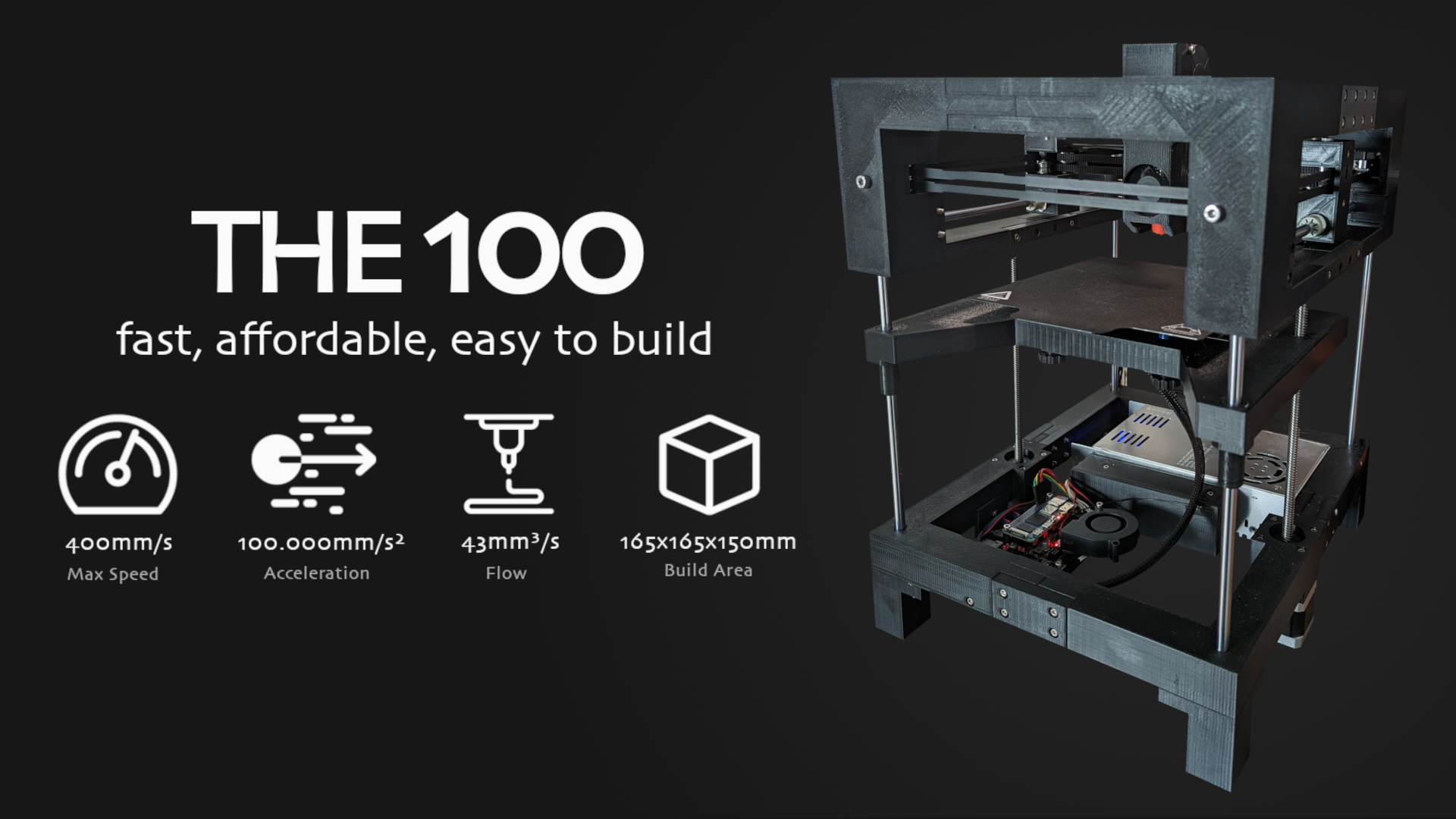

- Printing Technology: FDM

- Build Volume: 165x165x150mm

- Maximum Printing Speed: 400mm/s

- Maximum Acceleration: 100.000mm/s²

- Layer Height: 0.1-0.35mm

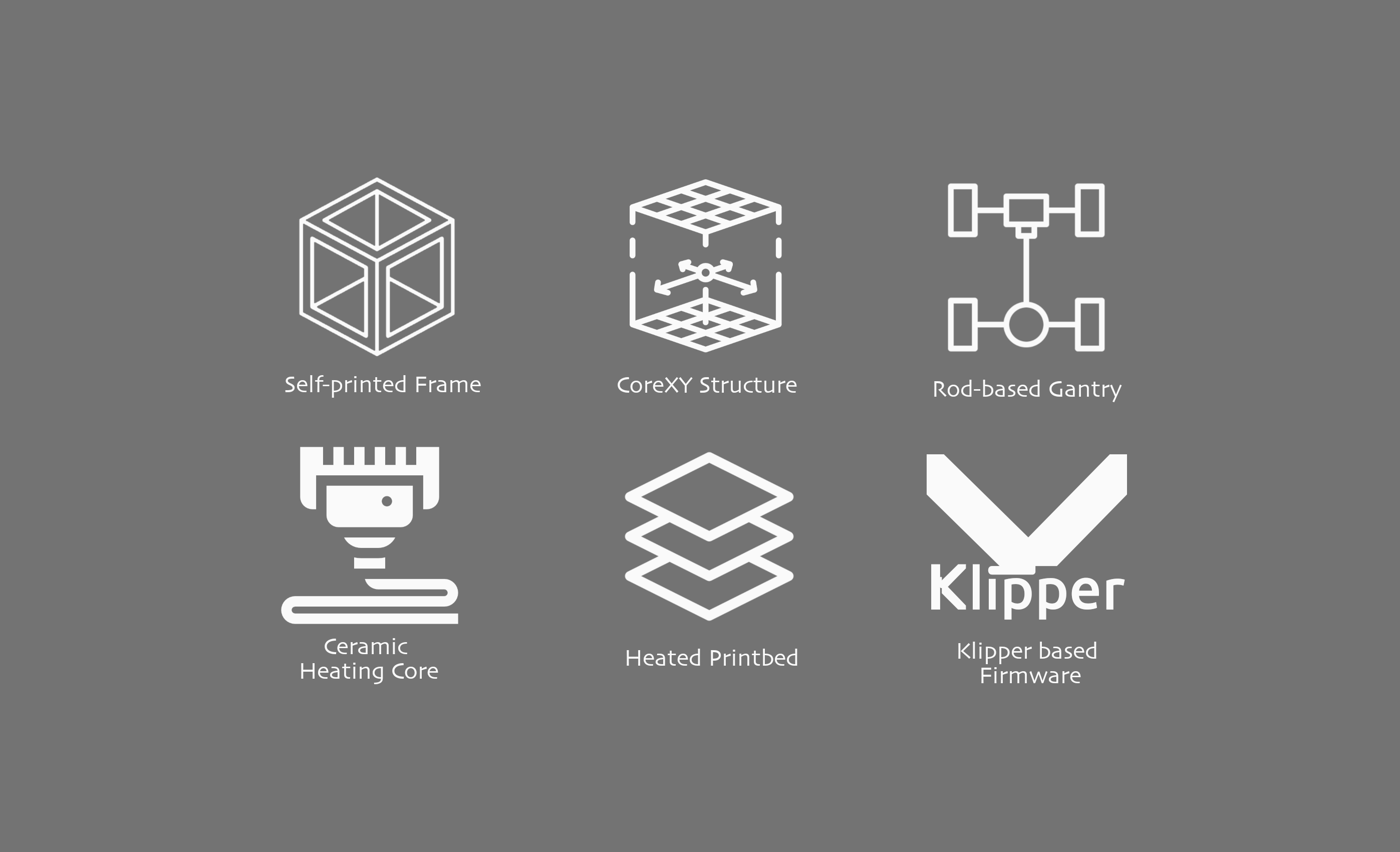

- Extruder: BMG Bowden Extruder

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4 (swappable)

- Maximum Nozzle Temperature: 300°C

- Maximum Heatbed Temperature: 110°C

- Leveling Mode: manual

- File Transfer: USB Drive, WIFI

- Rated Power: 350W

- Supported Filaments: PLA, PETG